STATIC FIRING TEST REPORT 25TH MARCH 2021

Motor Design

The propellant of choice was Potassium Nitrate(Oxidizer) and Dextrose(Fuel/Binder). An oxidizer to fuel ratio of 65%:35% was used. The propellant was cast into one grain with a total weight of 24g.

The grains had an outside diameter of 24mm and a core diameter of 7.2mm.

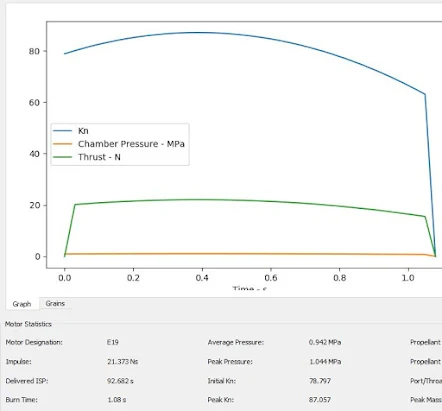

Prior to static testing a simulation using openMotor was done for a theoretical performance of the motor.

Motor Casing

The casing of the motor was made from ¾ inch PVC. The top side(bulkhead), as well as the nozzle, were to be made from tile cement.

The nozzle was designed with the following dimensions:

Throat diameter - 6 mm

Exit diameter - 6 mm

Throat length - 35mm

Divergence half angle - 0 degrees

Convergence half angle - 0 degrees

Motor Fabrication

The nozzle and endcap were fabricated using tile cement(grout).

The grout is mixed with water in the ratio of 3:1 by weight and poured into the pipe. The cast is left to sit overnight. The nozzle is made by drilling the hole with a 5mm drill bit. This resulted in a straight nozzle as designed. A failed firing resulted in a slight increase in nozzle diameter to about 6mm.

Static Firing Test

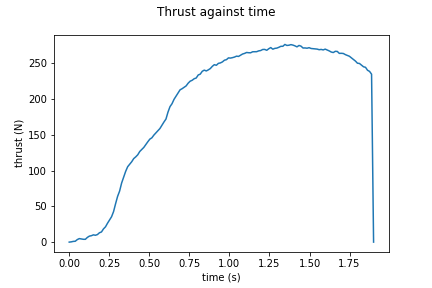

Results

- Total Impulse: 3.95 N-sec

- Specific Impulse: 164.75 N-sec/Kg

- Average Thrust: 1.36 N

- Motor Class: B

- Burn time: 2.9s

Sources of Error

- The sampling rate of the program. Due to the addition of live animation to the program used to record load cell data, the sampling rate was drastically reduced due to the time taken to generate animations.

- The nozzle diameter was slightly increased when a plug from the pyrogenic igniter had blocked it. This might have decreased chamber pressure by 30% for a 1mm increase.

- The pyrogenic igniter failed to start the motor and resulted in a blockage of the nozzle.

Recommendations

- Separating data sampling from the load cell from the live plot animation.

- Make a shorter pyrogenic igniter.

Comments

Post a Comment