Rocket Propulsion:

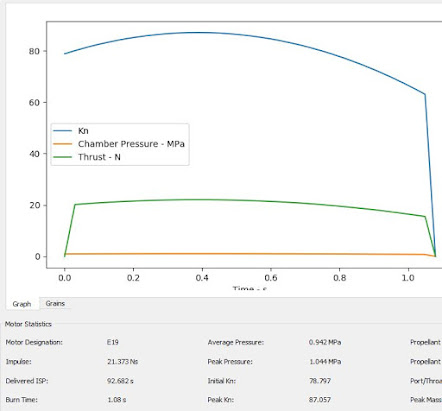

Theory: · Rocket motion is based on Newton’s second law of motion ( 𝐹 = 𝑚𝑎 ). · Rocket motion is a variable mass problem i.e rocket mass changes as the propellant is used up. · Air density varies with altitude. · In flight, a rocket is subjected to four forces: thrust, lift, drag, and weight. Governing equations: 1. Drag equation 𝐷𝑟𝑎𝑔 𝑓𝑜𝑟𝑐𝑒 = 𝐶𝑑 ∗𝜌𝐴𝑣/ 2 Where: a) Cd=drag co-efficient (obtained from the NASA’s Glenn Research Centre website) b) Ρ=air density (I used the ISA model because using the standard ideal value of 1.2kg/m3 would not reflect the practical air density conditions encountered during rocket flight) c) A= rocket area (frontal) N/B: the area used i.e whether surface or frontal affects the drug force d) V= rocket velocity 2. Weight 𝑤 = 𝑚 ∗ 𝑔 MATLAB Simulation Model About the Model: · Thrust is imported from excel file into a work space variable. I